Structural Foam Market to Surpass USD 152.9 Billion by 2035, Driven by Lightweighting & Sustainable Manufacturing Trends

Polypropylene will dominate with a 37.9% market share, while injection molding will lead the molding process segment with a 41.2% share.

NEWARK, DE, UNITED STATES, November 12, 2025 /EINPresswire.com/ -- According to Future Market Insights (FMI), the global structural foam market is poised for steady expansion, growing from USD 106.4 billion in 2025 to USD 152.9 billion by 2035, at a compound annual growth rate (CAGR) of 3.7%. This growth underscores a transformative shift in industrial materials as manufacturers increasingly adopt lightweight, rigid, and energy-efficient foamed polymers across construction, automotive, and packaging applications.

Stable Global Growth Anchored in Design Efficiency

Between 2025 and 2030, the market is projected to advance from USD 88.8 billion to USD 110.3 billion, marking a cumulative gain of 24.2% and an annualized growth rate of 4.4%. FMI’s data analysis indicates a consistent year-over-year increase of USD 3.2–3.9 billion, reflecting a structurally stable expansion driven by lightweight substitution in metal and solid plastic components.

The market’s growth trajectory is sustained by rising industrial automation, advances in low-pressure foam molding, and stringent efficiency mandates across North America, Europe, and Asia-Pacific. FMI analysts attribute the surge in adoption to the material’s unique blend of low density, high rigidity, and dimensional stability, making it indispensable in modern high-volume production systems.

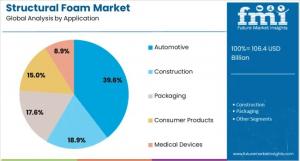

Automotive and Construction Sectors Lead Global Demand

The building and construction industry dominates the global structural foam market, accounting for 42–43% of total demand in 2025. Foam-based insulation panels, formworks, and modular wall systems are increasingly utilized to reduce load while maintaining structural strength. The automotive and transportation sector follows with 35–40% share, as automakers embrace foamed polymers to achieve up to 30% weight reduction in panels, seat frames, and underbody structures—critical for improving fuel efficiency and EV range.

“Manufacturers are rethinking design paradigms—structural foam’s ability to integrate multiple features within a single molded part significantly reduces assembly time, weight, and material cost,” said an FMI analyst.

Packaging, electrical, and consumer goods sectors jointly account for around 20% of market share, leveraging foam’s recyclability, flame resistance, and vibration absorption for durable goods, housings, and reusable transport systems.

Subscribe for Year-Round Insights → Stay ahead with quarterly and annual data updates: https://www.futuremarketinsights.com/reports/sample/rep-gb-22998

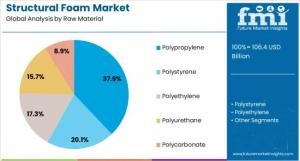

Material Insights: Polypropylene Maintains Dominance

Polypropylene continues to lead, capturing 37.9% of the total revenue share in 2025. Its combination of impact strength, moisture resistance, and cost efficiency makes it the preferred structural foam base. FMI’s research highlights that polypropylene’s recyclability and compatibility with gas-assisted foam molding reinforce its adoption in automotive interiors, battery enclosures, and logistics crates.

Injection Molding Accounts for Over 41% of Market Revenue

The injection molding segment remains pivotal, contributing 41.2% of total revenue in 2025. Its precision in creating thick-walled, high-strength parts with minimal waste continues to attract manufacturers seeking consistent performance and reduced cycle times. Integration of gas-assist technologies and automated process control has strengthened its footprint across the automotive, appliance, and consumer goods sectors.

Regional Insights: Asia-Pacific Leads Global Expansion

Asia-Pacific (APAC): Fastest-Growing Structural Foam Market

The APAC region dominates global growth, with China and India leading in capacity expansion and adoption.

- China is projected to grow at a 5.0% CAGR, supported by the proliferation of low-pressure injection facilities and demand from automotive, appliance, and modular furniture production.

- India, growing at 4.6% CAGR, is witnessing rapid uptake in automotive interiors, electrical enclosures, and housing infrastructure, fueled by domestic manufacturing programs and smart city projects.

Rising domestic investment in lightweight construction, packaging logistics, and EV manufacturing positions APAC as a key production hub for foamed polymer systems through 2035.

Europe: Engineering-Driven Expansion

Europe remains at the forefront of innovation and regulatory compliance, posting an average regional CAGR of 3.9–4.2% led by Germany, France, and the U.K.

- Germany’s 4.2% CAGR reflects widespread adoption of structural foam in machinery housings, automotive systems, and insulation boards, aided by material replacement of heavy plastics and metals.

- France (3.9% CAGR) and the U.K. (3.5% CAGR) are scaling production of construction panels, modular housing parts, and marine components, focusing on durability and reduced emissions.

European producers are prioritizing multi-cavity molds, energy-efficient processing, and bio-based foamed polymers to align with sustainability targets and circular economy directives.

United States: Innovation in Lightweight Vehicle Platforms

The U.S. structural foam market—valued at over USD 25 billion in 2025—is projected to expand at a 3.1% CAGR through 2035. Growth is driven by increasing use of foam in vehicle seating, crash protection modules, and under-hood components, alongside the push for electric vehicle modularization. U.S. OEMs are integrating foam molding into high-throughput assembly lines to meet lightweighting mandates without compromising crash performance.

Saudi Arabia: Emerging Growth in Industrial Infrastructure

In the Kingdom of Saudi Arabia, demand for structural foam is strengthening in construction, oil & gas support systems, and industrial packaging as Vision 2030 projects advance large-scale infrastructure initiatives. FMI forecasts steady growth led by domestic production partnerships and import substitution in insulation, prefabricated housing, and equipment casing applications.

Gain complete access to the report for extensive coverage of market forecasts, competitive benchmarking, and evolving industry trends! Buy Full Report: https://www.futuremarketinsights.com/checkout/22998

Key Growth Drivers and Industry Trends

- Lightweight Reinforcement & Energy Efficiency: OEMs are adopting structural foam for high-strength, low-mass components, particularly in electric mobility and modular construction.

- Localized Compounding & Process Optimization: Regional compounding hubs are shortening supply chains, while tooling alliances enable better control of cell morphology and expansion uniformity.

- Regulatory Support: Emission and recyclability mandates in the EU and North America are accelerating foam adoption across packaging and transport infrastructure.

- Technology Integration: Closed-loop process controls and AI-driven quality inspection are enhancing foam consistency and reducing scrap rates.

Competitive Landscape

The global structural foam market features a balanced mix of Tier 1 chemical producers, Tier 2 process specialists, and Tier 3 regional molders. These participants collectively focus on polymer innovation, process efficiency, and composite integration. Leading companies are investing in renewable-powered facilities and bio-based foam formulations to meet carbon-neutral production goals.

Future Outlook

Through 2035, FMI anticipates structural foam’s penetration to deepen across EV platforms, reusable packaging, and sustainable construction materials. Innovation in thermoplastic composites, cell structure control, and automated molding systems will define competitive differentiation.

Exploring Insights Across Emerging Global Markets:

PV Module Encapsulant Film Market: https://www.futuremarketinsights.com/reports/pv-module-encapsulant-film-market

Wind Turbine Blade Repair Material Market: https://www.futuremarketinsights.com/reports/wind-turbine-blade-repair-material-market

Phthalate and Non-Phthalate Plasticizers Market: https://www.futuremarketinsights.com/reports/phthalate-and-non-phthalate-plasticizers-market

Malonic Acid Market: https://www.futuremarketinsights.com/reports/malonic-acid-market

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Why Choose FMI: Empowering Decisions that Drive Real-World Outcomes: https://www.futuremarketinsights.com/why-fmi

Sudip Saha

Future Market Insights Inc.

+18455795705 ext.

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.